Guiding the company

- Bachelor of Science in Economics

- Oregon State University

- 1979

- Master of Arts in Interdisciplinary Studies – Economic Development

- Cultural Anthropology, History and Sociology

- Oregon State University

- 1983

I went to the USA to study Animal Science, but I found the production systems so different from the reality of Bolivia that I switched to Economics to study how different cultures develop their economies.

Building my house

The highlands of Bolivia

Back in La Paz, Bolivia, I joined a small packaging factory. After a couple of years I moved to Santa Cruz, where I continued to create packaging suitable for exportable products. I built a business that designed, offered prepress service, high fidelity printing and die cutting.

When internet access became available in Santa Cruz we also became an internet service provider. We not only gave access to the internet but also became a web site and multimedia design company, always with the objective to promote exportable products.

After a couple of years an opportunity opened to participate in the export of high quality flooring to Japan, I decided to join. Sold the tech business and became a logger and sawmill manager.

Living the jungle life in the Amazon basin was exciting. I got to see very remote areas of Bolivian that few people will reach. I learned a lot about wood species, and how to log and process flooring for the rigorous quality demanded by Japan.

Ipe logs

My first timber frame roof

But logging conditions in Bolivia are difficult therefore expensive, and the added value for flooring was not that significant. After 5 years we closed the sawmill and I moved to La Paz with some leftover pieces of rough cut timber.

I presented the wood in a construction fair and someone asked me to do a timber frame roof for a salon.

Creating beautiful timber frame roofs with extremely hard wood was a great challenge. Eastern white pine has an average dried weight of 400kg/m3. The wood I had available was Cumaru, with a dried weight of 1,085kg/m3. In the pictures below you can view what we accomplished.

La Paz was a good market for that business, but timber frame structures are really not exportable, so after a few years over there I came back to Santa Cruz, where I presently live.

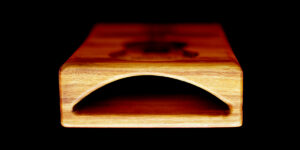

Wood species in the Santa Cruz forest are different, some hardwoods are so hard they are unworkable, but there are some precious woods that are suitable for small elaborate products that can be exported.

Finally I have a beautiful product that I can export. I am designing the packaging, creating my website, adapting machinery, and carefully crafting a product that I can be proud to deliver to you.